Important Information - Brew2Bottle

Important Information

UPDATE

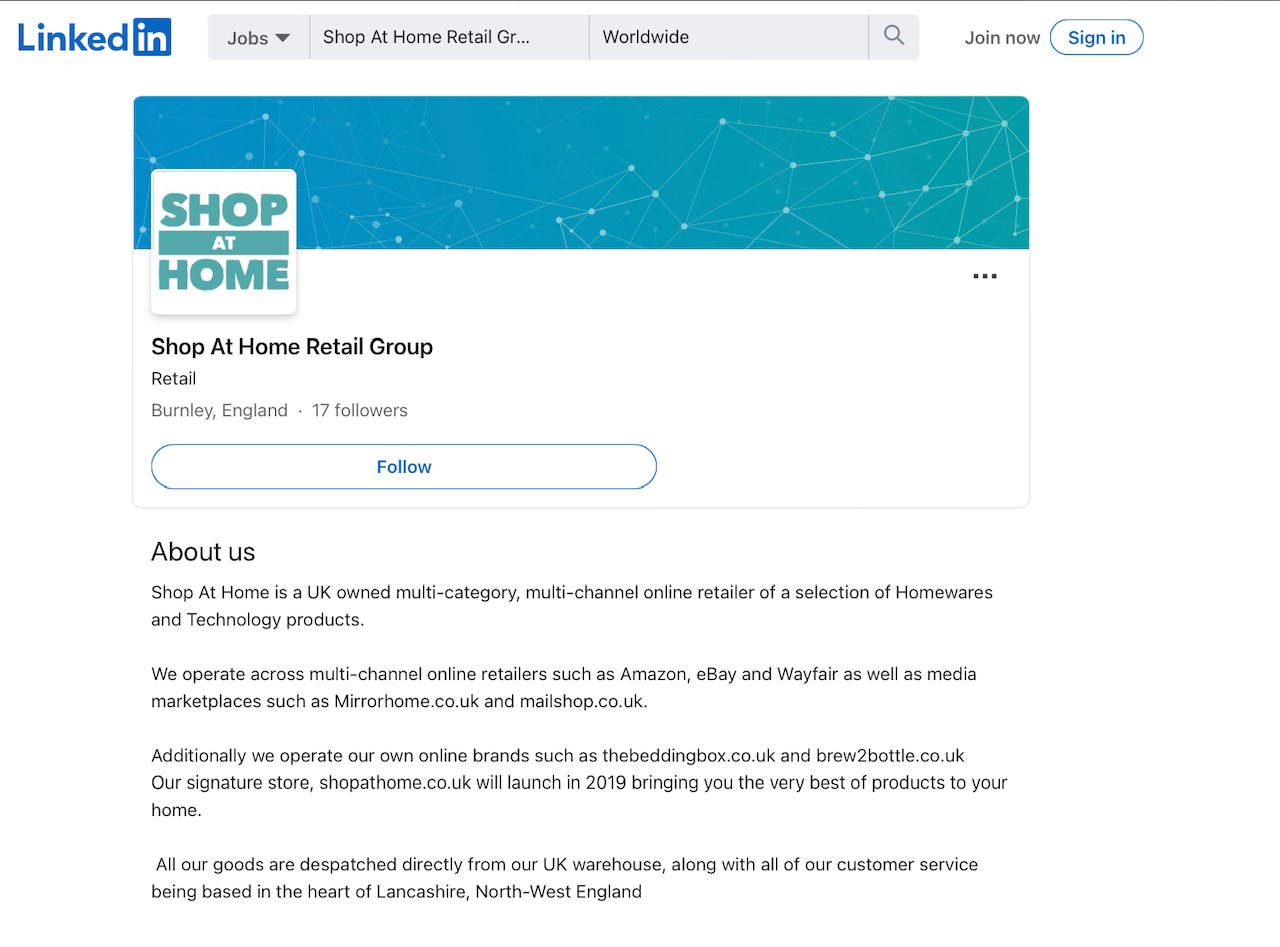

We have been advised that Brew 2 Bottle Ltd / Virtual Distribution has been purchased back by 2 of the serving officers. Absolute classic !!!

The new company is SHOP AT HOME RETAIL GROUP LIMITED. Company number 1068694. This company was created in Feb 2017.

So be very very wary, when it 'pops' back up to start trading.

Thursday 31st March 2022

UPDATE

As we have seen on several forums with regards to the "company restructuring".

On Friday 18th March, we recieved official documentation that "Brew2Bottle / Virtual Logistics" was entering volentary liquidation. So with regards to Forum comments, they should not be processing any further orders from the appointment of the Insolvency Practisioner.

You can see, there is no stock from any of the Home Brew Suppliers. What we will say, is they owe a considerable amount of money, to 42 other Creditors.

Please consider whether you wish to support such a company.

Friday 25th March 2022

UPDATE

Tuesday 8th March we were contacted by an Insolvency Practitioner acting on behalf of Brew2Bottle. Our understanding, appointed 1st March. We have done as much as we can to try and resolve the issue. The further problem ( and frustrating as it is ), they are still allowed to trade, but rest assured - no stock will appear.

When we took the decision to act in the way that we have, it wasn’t taken lightly. We are a longstanding company. What we could see happening was Brew2Bottle was about to ‘bring down’ other suppliers within our industry.

There is some chatter on some ‘Home Brew Forums’. From our understanding and more importantly to put the story right, they have been asked to clarify and put their side of the story across ( even as a sponsor ) , which they have declined. So, what do they have to hide?. They can freely put their side of this matter anywhere they wish.

What needs to be understood is this is not the first time that some of the serving officers have done this. The last thing we would want is for anyone to place orders, only to find the goods were never ( and knowingly ) going to be delivered. You’re hard-earned cash simply gone.

If we hadn’t done what we have, customers ( you ) of B2B would still be placing orders with them, oblivious to what was happening in the background.

This is a business model used well. Setting up companies in anticipation of folding the previous.

We could not sit back and be used in the manor of “ it’s a supply issue “ damaging our company, brands, and reputation. Rest assured, our stocks are plentiful.

Look these people up on ‘social media’. Look at the companies they are attached to.

Some companies in our industry possibly cannot afford to lose monies and this could spell the end for them too, no one gives that a thought ?, other lively hoods gone.

Less suppliers = less choice= less stock= less stores. Clearly, they have no morals or obligations.

Friday 11th March 2022

UPDATE

We have now had no alternative but to issue a 'Winding Up Petition' against the company 'Brew2Bottle' and its serving officers for failure to make payment.

Serving Officers -

Stephen John Ackers

Gareth Clarkson

Charles Vernon Yerkess

Sara Wilson

4th March 2022

We want to make customers of Brew2Bottle, Hapton. Lancashire, aware of issues with the supply of Home Brew products.

For several weeks, we have not supplied products for sale to this company. You will see from their website that stocks are at a minimum or majority out of stock.

What does this mean for you the customer? In the current financial situation all of us face, we feel it duly right that should you be purchasing items from this company (and or any other in fact ) you are made aware that any “promissory notes” to sell you item’s ( especially were out of stock ) are not an issue with stock being available from ourselves or in fact many of our trading partners.

It’s easy for a “virtual company” to pass the blame of product availability/supply back to a manufacture or their supplier, especially if you can’t physically see it or touch it.

Young’s have been in the industry for over 50 years, from the very beginning of manufacturing and supplying Home Brew products, to which we are extremely proud & honourable. We feel it morally correct that should you part with hard earned funds, you receive the items you ask for and not broken promises.

23rd Febuary 2022

How To Make Wine

|

|

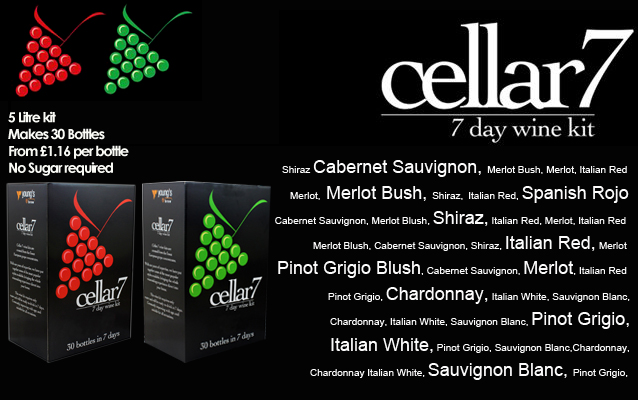

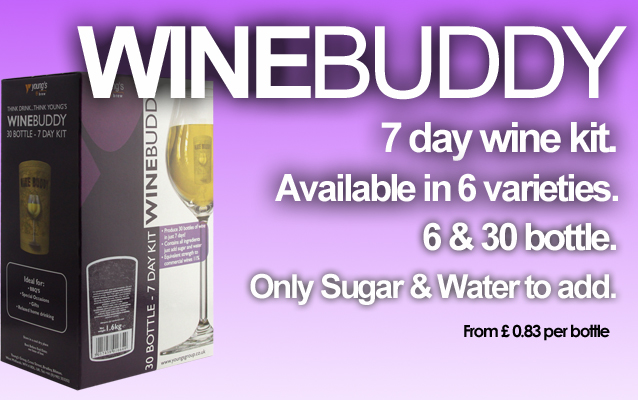

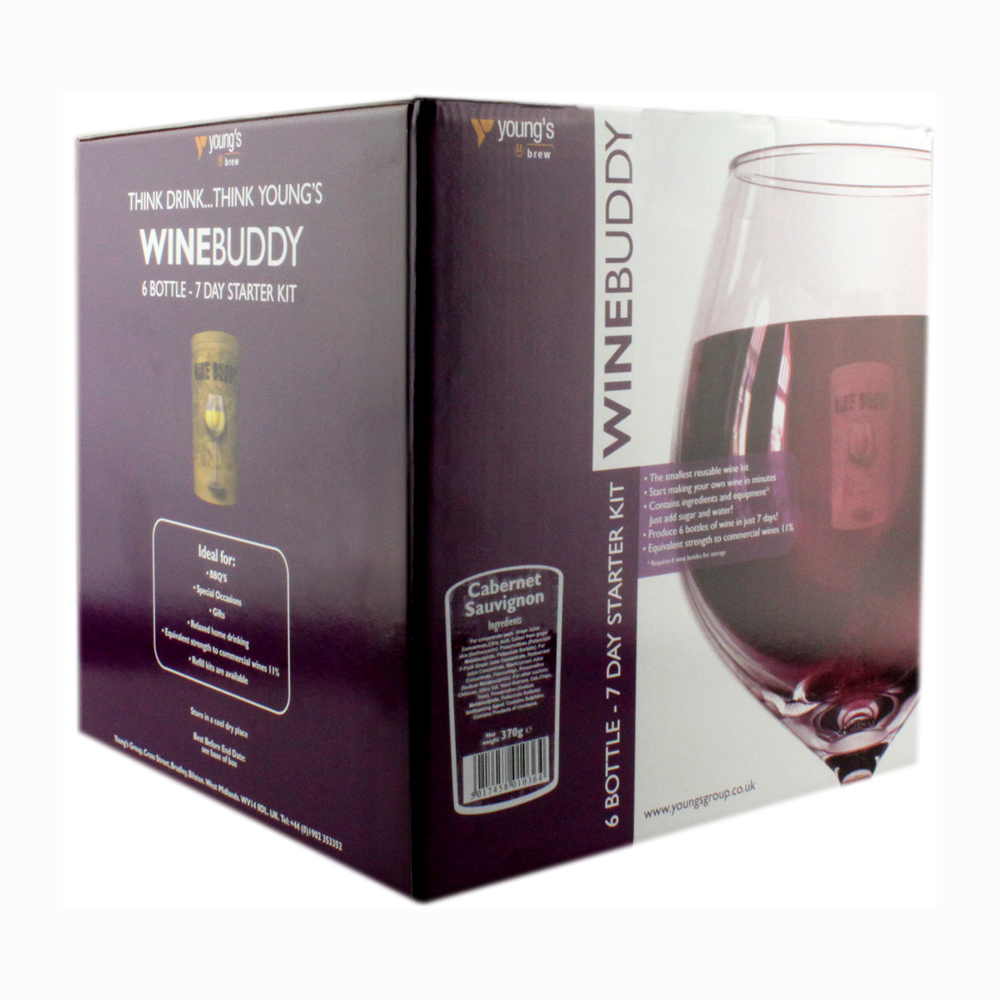

All wine kits include easy to follow detailed instructions. It has never been easier to produce quality wines in your own home. Kits make 6 or 30 bottles consisting of quality ingredients giving you superb results every time.

What will I need? ( Based on 30 bottle wine kit )

The wine kit of your choice Hydrometer / Trial jar ( recommended ) * Not all kits require suger

How Do I Do It? Please ensure you carefully read your wine kit instructions before starting your wine. It's also a good idea to double check your kit contents before starting. We cannot stress enough how important it is to thoroughly sterilse all equipment before use. We recommend using Young's Cleaner / Steriliser. Empty the juice into the fermenter / vessel. Your kit instructions will advise the required amount of water, we recommend you add 50 / 50 - Hot ( not boiling ) / Cold, adding hot first and stirring thoroughly. If your kit requires sugar - use the hot water to help dissolve it. After making sure the Juice / Water / Sugar is thoroughly mixed, use your Hydrometer and take a note of the reading. This will not only make sure you have thoroughly mixed but will help you determine your alcohol content at the end. Add the Yeast / Bentonite and ensure the fermenter lid is tightly closed, fit the bung and airlock (containing water). Fermentation should start within 48 hours. This is shown by bubbles passing through the airlock. A constant temperature will produce a more stable fermentation. Temperature variations may effect fermentation. When the "bubbles" have stopped or slowed in the airlock, check wine has finished using your Hydrometer. You can also taste the wine at this stage to see if it suits your palate. As a guide, this is how your wine will taste. 990 - 994 = Dry 995 - 999 = Medium 1000 - 1005 = Sweet In order to work out your alcohol content, take your starting gravity minus ( - ) your finishing gravity and divide by 7.41. As an example - 1.090 - 1.000 = 90 Divide 90 by 7.41 = 12.14% ABV. Once the wine has finished add the stabiliser and "De Gas". De Gassing the wine is a simple process of removing the Co2 from the wine. Either stir or shake the wine, a "foamy head" will appear. Repeat this during the day over 2-3 days until all the foam has nearly all gone. De Gassing also helps with clearing. You will then add the finings, after around a week your wine should be crystal clear & ready for bottling / dispensing. Enjoy. |

|

Instructions

| Beer / Cider Instructions | |||

| Wine Kit Instructions | |||

| |

|||

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

Starter Kits |

|||

|

|

|

||

How To Make Beer

|

|

All beer kits include easy to follow detailed instructions. It has never been easier to brew your own beer. Using the finest quality ingredients, malt, hops and yeast to give you a great pint time and time again.

What will I need? ( Based on 40 pint kit )

The beer kit of your choice Hydrometer / Trial jar ( recommended ) Brewing Sugar / Beer Enhancer* * Not all kits require sugar ** For Barrelling only

How Do I Do It? Please ensure you carefully read your beer kit instructions before starting your beer kit. It's also a good idea to double check your kit contents before starting. We cannot stress enough how important it is to thoroughly sterilse all equipment before use. We recommend using Young's Cleaner / Steriliser. It may help to remove the lid, stand the can / pouch in hot (not boiling) water for up to 5 minutes, to help loosen up the malt to help pouring. Empty the malt into the vessel. Your kit instructions will advise the required amount of water, we recommend you add 50 / 50 - Hot ( not boiling ) / Cold, adding hot first and stirring thoroughly. If your kit requires sugar - use the hot water to help dissolve it. After making sure the Malt / Water / Sugar is thoroughly mixed, use your Hydrometer and take a note of the reading. This will not only make sure you have thoroughly mixed but will help you determine your alcohol content at the end. Add the Yeast / Hops and ensure the fermenter lid is tightly closed, fit the bung and airlock (containing water). Fermentation should start within 48 hours. This is shown by bubbles passing through the airlock. A constant temperature will produce a more stable fermentation. Temperature variations may effect fermentation. When the "bubbles" have stopped or slowed in the airlock, check the beer has finished using your Hydrometer. Refer to your beer kit instructions as this will tell you when the specific gravity of when you can Barrel / bottle your beer. In order to work out your alcohol content, take your starting gravity minus ( - ) your finishing gravity and divide by 7.41. As an example - 1.0400 - 1.0100 = 30 Divide 30 by 7.41 = 4.05% ABV. Once the beer has finished you then need to prime the beer, some will recommend half a tea spoon per bottle or around 80grams for a Barrel. The easiest way we find is to "bulk prime". Simply transfer your beer into another sterilised vessel, add the full amount of sugar, mix thoroughly stiring well. This ensures that the sugar is equally dissolved in all of the wort. Beer finings may also be added at this stage should you wish. If transfering the wort into a Barrel (sterilised), make sure the "cap o'ring" has a smear of Vaseline to ensure an air tight seal. Its also a good idea to check the tap to make sure it is tight. If ottling ensure you leave a little head room for the Co2 to form. Leave for around 2 weeks. This will give the beer time to carbonate and clear. Enjoy. |

|

Website Terms and Conditions

Welcome to our website. If you continue to browse and use this website, you are agreeing to comply with and be bound by the following terms and conditions of use, which together with our privacy policy and our cookie policy govern Young's Home Brew Limited’s relationship with you in relation to this website. If you disagree with any part of these terms and conditions, please do not use our website. The term ‘Young's Home Brew Limited’ or ‘us’ or ‘we’ refers to the owner of the website whose contact details can be found on our contact page. The term ‘you’ refers to the user or viewer of our website. The use of this website is subject to the following terms of use:

- The content of the pages of this website is for your general information and use only. It is subject to change without notice.

- This website uses cookies and may not function correctly without them. By using our website and agreeing to these terms and conditions you are consenting to our use of cookies in accordance with our cookie policy. Please refer to our cookie policy for further information.

- Neither we nor any third parties provide any warranty or guarantee as to the accuracy, timeliness, performance, completeness or suitability of the information and materials found or offered on this website for any particular purpose. You acknowledge that such information and materials may contain inaccuracies or errors and we expressly exclude liability for any such inaccuracies or errors to the fullest extent permitted by law.

- Your use of any information or materials on this website is entirely at your own risk, for which we shall not be liable. It shall be your own responsibility to ensure that any products, services or information available through this website meet your specific requirements.

- This website contains material which is owned by or licensed to us. This material includes, but is not limited to, the design, layout, look, appearance and graphics. Reproduction is prohibited other than in accordance with the copyright notice, which forms part of these terms and conditions.

- All trademarks reproduced in this website, which are not the property of, or licensed to the operator, are acknowledged on the website.

- Unauthorised use of this website may give rise to a claim for damages and/or be a criminal offence.

- From time to time, this website may also include links to other websites. These links are provided for your convenience to provide further information. They do not signify that we endorse the website(s). We have no responsibility for the content of the linked website(s).

- Your use of this website and any dispute arising out of such use of the website is subject to the laws of England, Northern Ireland, Scotland and Wales.

Disclaimer

The information contained in this website is for general information purposes only. The information is provided by Young's Home Brew Limited and while we endeavour to keep the information up to date and correct, we make no representations or warranties of any kind, express or implied, about the completeness, accuracy, reliability, suitability or availability with respect to the website or the information, products, services, or related graphics contained on the website for any purpose. Any reliance you place on such information is therefore strictly at your own risk.

In no event will we be liable for any loss or damage including without limitation, indirect or consequential loss or damage, or any loss or damage whatsoever arising from loss of data or profits arising out of, or in connection with, the use of this website.

Through this website you are able to link to other websites which are not under the control of Young's Home Brew Limited. We have no control over the nature, content and availability of those sites. The inclusion of any links does not necessarily imply a recommendation or endorse the views expressed within them.

Every effort is made to keep the website up and running smoothly. However, Young's Home Brew Limited takes no responsibility for, and will not be liable for, the website being temporarily unavailable due to technical issues beyond our control.

Privacy

This privacy policy sets out how Young's Home Brew Limited uses and protects any information that you give Young's Home Brew Limited when you use this website.

Young's Home Brew Limited is committed to ensuring that your privacy is protected. Should we ask you to provide certain information by which you can be identified when using this website, then you can be assured that it will only be used in accordance with this privacy statement.

Young's Home Brew Limited may change this policy from time to time by updating this page. You should check this page from time to time to ensure that you are happy with any changes.

What we collect

We may collect the following information:

- name and job title

- contact information including email address

- demographic information such as postcode, preferences and interests

- other information relevant to customer surveys and/or offers

What we do with the information we gather

We require this information to understand your needs and provide you with a better service, and in particular for the following reasons:

- Internal record keeping.

- We may use the information to improve our products and services.

- We may periodically send promotional emails about new products, special offers or other information which we think you may find interesting using the email address which you have provided.

- From time to time, we may also use your information to contact you for market research purposes. We may contact you by email, phone, fax or mail. We may use the information to customise the website according to your interests.

Security

We are committed to ensuring that your information is secure. In order to prevent unauthorised access or disclosure, we have put in place suitable physical, electronic and managerial procedures to safeguard and secure the information we collect online.

How we use cookies

Cookies help us provide you with a better website, by enabling us to monitor which pages you find useful and which you do not. A cookie in no way gives us access to your computer or any information about you, other than the data you choose to share with us. You can choose to accept or decline cookies. Most web browsers automatically accept cookies, but you can usually modify your browser settings to decline cookies if you prefer. This may prevent you from taking full advantage of the website. You can find out more about cookies and how to control them from your browser by visiting http://www.aboutcookies.org/. Our use of cookies is described more fully in our cookie policy.

Links to other websites

Our website may contain links to other websites of interest. However, you should note that we do not have any control over that other website. Therefore, we cannot be responsible for the protection and privacy of any information which you provide whilst visiting such sites and such sites are not governed by this privacy statement. You should exercise caution and look at the privacy statement applicable to the website in question.

Controlling your personal information

We will not sell, distribute or lease your personal information to third parties unless we have your permission or are required by law to do so. We may use your personal information to send you promotional information about third parties which we think you may find interesting if you tell us that you wish this to happen. You may request details of personal information which we hold about you under the Data Protection Act 1998. A small fee will be payable. If you would like a copy of the information held on you please write to the address shown on our contact page. If you believe that any information we are holding on you is incorrect or incomplete, please write to or email us as soon as possible, at the above address. We will promptly correct any information found to be incorrect.

Accessibility

Young's Home Brew Limited aims to make our website accessible and usable by people of all abilities and disabilities, including those with visual, hearing, cognitive or motor impairments.

Many people use assistive technologies to allow them to adjust their experience of a website to make it easier for them to use. For example, they might view a website in easier-to-read colours with larger fonts, they may choose to experience content as spoken text, or they may navigate around a site using the keyboard only. As these assistive technologies become more available and sophisticated, we want to ensure that our website continues to work well with them to deliver a good experience for all our users. We are actively working to increase the accessibility and usability of our website and in doing so we adhere to many of the available standards and guidelines.

Our web designers and developers, Clickingmad Ltd, use a range of methods and processes to ensure that our website is accessible to all users. For example, all images and hypertext links should include an alternative text description and tables should not be used to define the layout of the site. The site has been built using code compliant with W3C standards for HTML and CSS. The site displays correctly in current browsers and using standards-compliant HTML/CSS code means any future browsers will also display it correctly. However, whilst we strive to adhere to the accepted guidelines and standards for accessibility and usability, it may not always be possible to do so in all areas of the website. Furthermore, there may be visual differences when using different browsers and users with different devices will experience the website in different ways.

If you have any questions regarding the accessibility or usability of our website, please contact us through the contact page.